Jul. 24, 2024

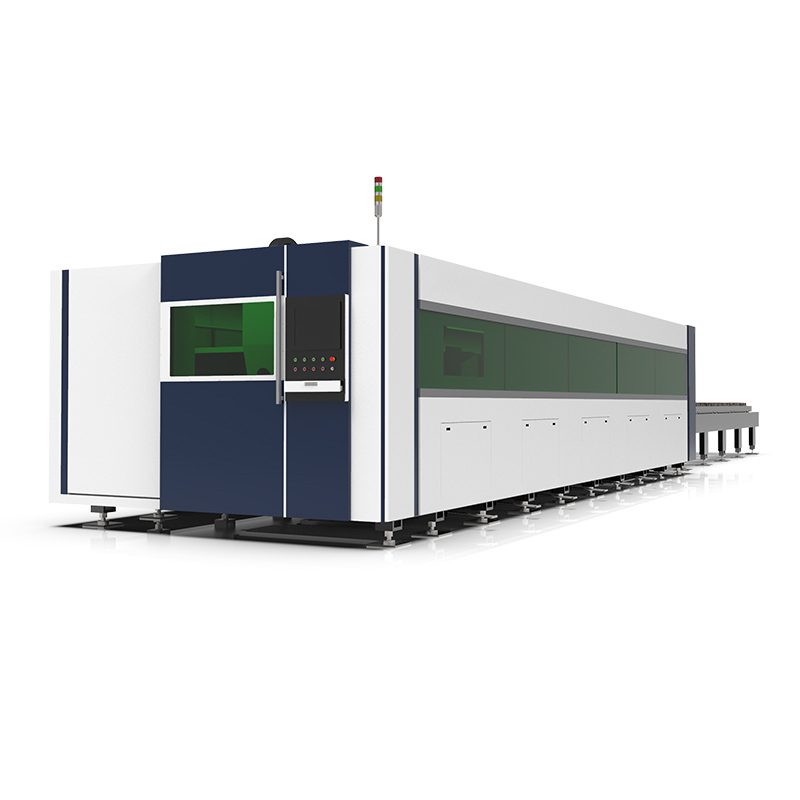

After using the stainless steel laser cutting machine for a certain period of time, there may be many problems, among which extending the life is one of them. We need to work hard to extend the life of the metal laser cutting machine. It is our common pursuit to buy a machine with a long service life at the same price. Everyone wants to make the metal laser cutting machine last longer, but the metal laser cutting machine requires our daily maintenance. Let's take a look at the methods to extend the life of the metal laser cutting machine.

Methods to extend the life of stainless steel laser cutting machine

1. Cleaning of water and water tank: It is recommended to clean the water tank and replace the circulating water once a week. It should be noted that the laser tube must be filled with circulating water before the machine works. The water quality and water temperature of the circulating water will directly affect the service life of the laser tube. It is recommended that users use pure water and control the water temperature below 35℃. If it exceeds 35℃, the circulating water needs to be replaced, or ice cubes are added to the water to cool it down (it is recommended that users use a cooler or two water tanks).

How to clean the water tank: First, turn off the power, unplug the water inlet pipe, let the water in the laser tube automatically flow into the water tank, open the water tank, take out the water pump, and remove the dirt on the water pump. Clean the water tank, replace the circulating water, restore the water pump to the water tank, insert the water pipe connected to the water pump into the water inlet, and tidy up the joints. Power on the water pump alone and run it for 2-3 minutes (so that the laser tube is filled with circulating water).

2. Clean the fan: Due to long-term use, a lot of solid dust will accumulate in the fan, causing the fan to make a lot of noise, which is not conducive to exhaust and deodorization. When the fan has insufficient suction or smoke exhaust, first turn off the power, remove the air inlet and outlet pipes on the fan, remove the dust inside, then turn the fan upside down, and pull the fan blades inside until it is clean, and then install the fan.

3. Clean the guide rail (it is recommended to clean it once every half a month, shut down the machine) The guide rail and linear axis are one of the core components of the equipment, and its function is to guide and support. In order to ensure that the laser cutting machine has a high processing accuracy, its guide rails and linear axes must have high guiding accuracy and good movement stability. During the operation of the equipment, a large amount of corrosive dust and smoke will be generated during the processing of the workpiece. These smoke and dust will be deposited on the surface of the guide rails and linear axes for a long time, which will have a great impact on the processing accuracy of the equipment, and will form corrosion spots on the surface of the guide rails and linear axes, shortening the service life of the equipment. In order to make the machine work normally and stably and ensure the processing quality of the product, it is necessary to do a good job of daily maintenance of the guide rails and linear axes.

In short, if you want to extend the life of the stainless steel laser cutting machine, it is essential to do a good job of cleaning and maintenance. If the metal laser cutting machine is often caught in complicated work without cleaning, it will definitely have a great impact on its life, so we should actively do it in this regard!

Previous: Master CNC IGBT Inverter Cutters: Elevate Your Metalwork!

Next: None

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

All Comments ( 0 )