Aug. 03, 2023

Machinery

Rolling machines, also known as roll forming machines, are a crucial component in the manufacturing and fabrication industries. These machines utilize a continuous bending process to shape metal sheets or strips into desired profiles. The process involves feeding the material through a series of rolls, which gradually shape it into the required form.

Rolling machines offer significant cost advantages over traditional fabrication methods. The continuous process reduces material wastage, leading to material savings. Moreover, the streamlined production process minimizes labor requirements, further reducing operational costs.

One of the key advantages of rolling machines is their versatility in handling various materials. Whether you need to work with steel, aluminum, copper, or other alloys, a well-designed rolling machine can adapt to different material thicknesses and properties.

Precision is paramount in manufacturing, and rolling machines excel in providing consistent and accurate results. The controlled bending process ensures that each product maintains uniformity in dimensions, eliminating the need for additional finishing or adjustments.

Time is of the essence in the industrial world. Rolling machines can operate at high speeds, significantly increasing production output. This efficiency allows businesses to meet tight deadlines and fulfill large-scale orders promptly.

With advancements in technology, modern rolling machines can be customized to produce a wide array of profiles and shapes. Manufacturers can tailor the machines to meet specific project requirements, giving them the flexibility to cater to diverse customer needs.

The continuous bending process of rolling machines enhances the structural integrity of the finished products. The absence of seams or joints in the profile improves its load-bearing capacity and resistance to external forces.

Automatic Rolling machine find extensive applications in various industries due to their versatility and efficiency. Let's explore some of the key areas where these machines play a pivotal role:

In the construction sector, rolling machines are used to create structural components such as beams, channels, and angles. These components form the backbone of buildings and infrastructure, ensuring stability and durability.

Featured content:The automotive industry benefits from rolling machines in the production of automotive parts and components. From body panels to chassis elements, rolling machines enable the fabrication of precision parts that meet strict quality standards.

Roll-formed profiles are commonly used in heating, ventilation, air conditioning, and refrigeration systems. The precise shapes and sizes achieved by rolling machines ensure seamless integration and optimal functionality of these systems.

The furniture and shelving industries rely on rolling machines to create metal profiles for various designs. These profiles offer enhanced strength and aesthetics, making them ideal for commercial and industrial furniture applications.

In the renewable energy sector, rolling machines are employed to produce components for solar panel frames and wind turbine structures. The high efficiency and accuracy of these machines contribute to the overall performance of renewable energy systems.

Aerospace and aviation industries utilize rolling machines to manufacture aircraft components with stringent dimensional requirements. The lightweight and durable profiles produced by these machines contribute to fuel efficiency and overall aircraft performance.

Roll-formed electrical enclosures are widely used to house electrical components, ensuring safety and protection in various applications.

In the agricultural sector, rolling machines play a vital role in manufacturing components for machinery and equipment, enhancing productivity and reliability in farming operations.

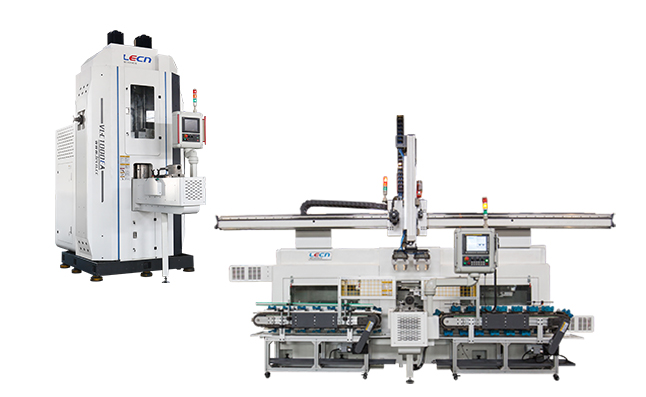

In conclusion, rolling machines offer numerous advantages and find extensive applications across various industries. At LECN, we understand the significance of these machines in modern manufacturing and are committed to providing cutting-edge solutions to meet your specific requirements.

If you are looking to improve your manufacturing processes, reduce costs, and enhance the quality of your products, investing in a top-of-the-line rolling machine is the way to go. Stay ahead of the competition and elevate your business to new heights with our innovative solutions.

Featured content:Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

All Comments ( 0 )